How To Repair Outside Tie Rod End On A 2006 Dodge Caravan

Introduction

Welcome to your guide on how to repair the outside tie rod end on a 2006 Dodge Caravan. The tie rod end is a crucial component of the steering system that connects the steering knuckle to the steering rack, allowing you to control the direction of your vehicle. Over time, the tie rod end may wear out or become damaged, leading to issues such as uneven tire wear, steering instability, and even compromised safety.

Repairing the outside tie rod end is a relatively straightforward task that can be completed with some basic tools and a little bit of patience. By following this step-by-step guide, you’ll be able to replace the worn or damaged tie rod end on your Dodge Caravan and restore the steering performance of your vehicle.

Before we dive into the repair process, it’s important to note that if you’re not confident in your mechanical abilities, it’s always best to consult a professional. Ensuring the safety of yourself and others on the road should be a top priority. However, if you’re up for the challenge and ready to get your hands dirty, let’s grab our tools and get started.

Tools and Materials Needed

Before embarking on the repair, gather the following tools and materials:

– Jack – Jack stands – Lug wrench – Socket set – Adjustable wrench – Tie rod end puller – Hammer – Grease – New tie rod end – Cotter pin – Torque wrenchThese tools are essential for safely and effectively completing the repair. The jack and jack stands will provide the necessary support to elevate the vehicle off the ground. The lug wrench is necessary for removing the wheel, while the socket set and adjustable wrench will be used to loosen and tighten various nuts and bolts.

A tie rod end puller is a specialized tool used to separate the tie rod end from the steering knuckle, making the removal process much easier. A hammer may also be needed to provide some gentle persuasion during the repair.

Grease is essential for lubricating the components and ensuring smooth operation and longevity of the tie rod end. It is important to use the appropriate grease recommended by your vehicle manufacturer.

Lastly, you will need a new tie rod end to replace the old or damaged one. Make sure to choose the correct tie rod end that is compatible with your 2006 Dodge Caravan model.

Additionally, a cotter pin is used to secure the tie rod end nut after installation, and a torque wrench is necessary to tighten the nuts to the correct specifications.

Having all these tools and materials ready before you start the repair will save you time and ensure a smoother process.

Step 1: Jacking up the Vehicle

The first step in repairing the outside tie rod end on a 2006 Dodge Caravan is to safely elevate the vehicle off the ground. This will provide the necessary clearance to access the components and perform the repair. Follow these steps:

- Find a flat and level surface to park your vehicle.

- Engage the parking brake to prevent the vehicle from rolling.

- Locate the appropriate jacking points on your vehicle. These are typically reinforced areas along the frame or chassis.

- Position the jack under one of these jacking points. Ensure that it is aligned properly and securely in place.

- Slowly begin to pump the jack handle to raise the vehicle. Keep an eye on the vehicle to ensure stability as it lifts off the ground.

- Raise the vehicle high enough so that the wheel on the side you will be working on is completely off the ground. This will allow for easier access to the tie rod end and other components.

- Once the vehicle is securely lifted, place jack stands under the recommended jacking points on the frame or chassis. This will provide additional support and safety while you work.

- Slowly lower the jack until the weight of the vehicle is resting on the jack stands. Give the vehicle a gentle shake to ensure it is stable and secure on the stands.

- Repeat this process on the opposite side of the vehicle if necessary, depending on which tie rod end you need to replace.

Remember, safety is paramount during this process. Always use proper jack stands and never work under a vehicle supported only by a jack. Take your time and ensure the vehicle is stable and secure before proceeding to the next step.

Step 2: Removing the Wheel

With the vehicle safely lifted and supported by jack stands, you can now proceed to remove the wheel on the side where you’ll be working. Removing the wheel will provide easier access to the tie rod end and other components. Follow these steps:

- Locate the lug nuts that secure the wheel to the hub.

- Using a lug wrench or a socket set, loosen the lug nuts but do not remove them completely.

- Place a jack stand or a block of wood behind the opposite wheel to prevent the vehicle from rolling.

- Once the lug nuts are loose, proceed to fully remove them.

- Gently grasp the wheel with both hands and give it a tug to loosen it from the hub. If it’s difficult to remove, you can gently kick the bottom of the tire to loosen it.

- With the wheel loose, carefully roll it away from the vehicle and set it aside in a safe location.

With the wheel removed, you now have a clear view of the tie rod end and can proceed with the removal and replacement process. Properly storing the wheel and lug nuts in a secure area will ensure they don’t roll away or get lost during the repair.

Remember to exercise caution when working around the wheel and hub area. Be mindful of your surroundings and keep a firm grip on the wheel to prevent any accidents or injuries.

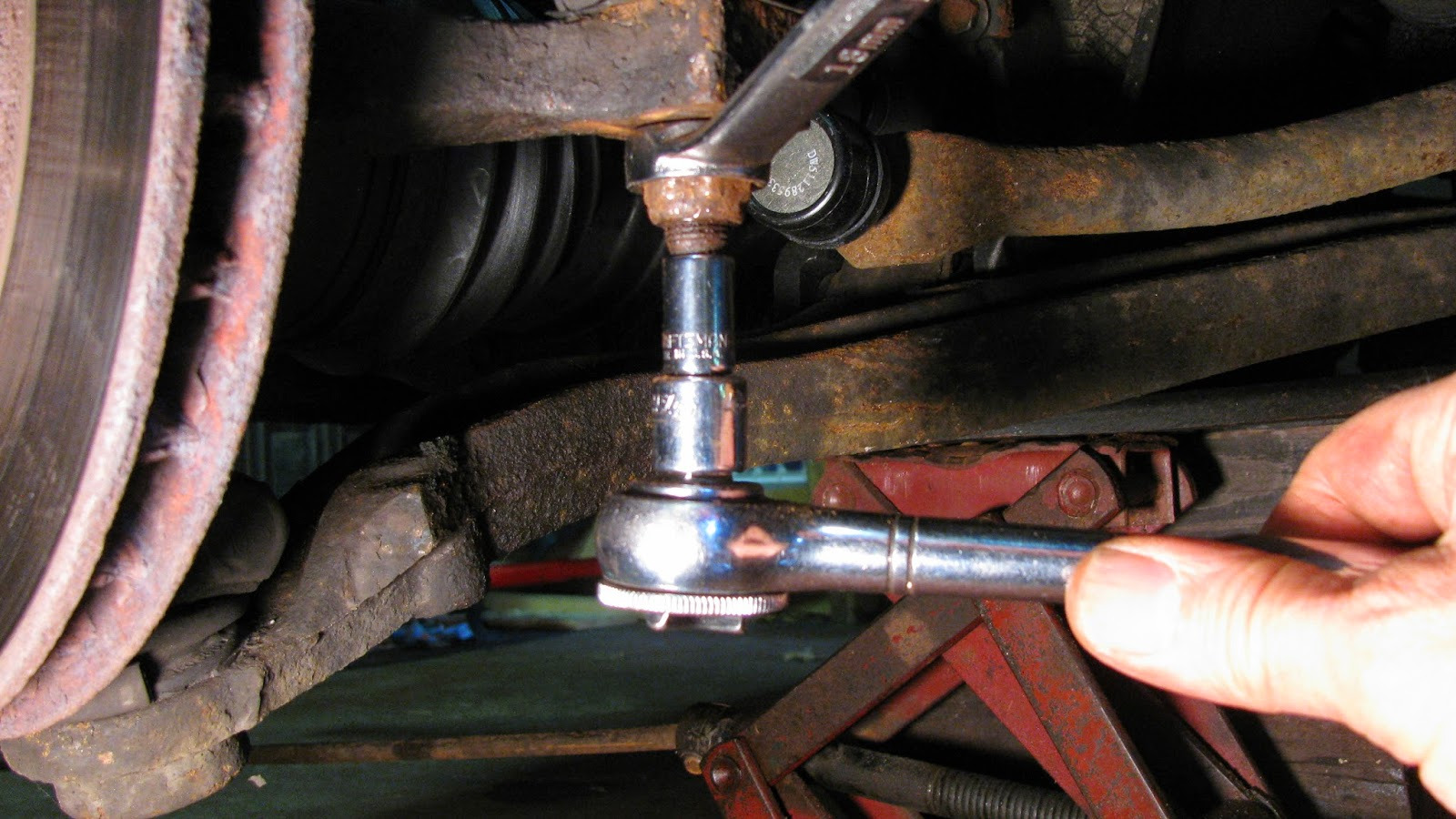

Step 3: Removing the Tie Rod End Nut

Now that the wheel has been removed, you can proceed to remove the tie rod end nut. This nut connects the tie rod end to the steering knuckle. Follow these steps:

- Locate the tie rod end and identify the nut that secures it to the steering knuckle. It is usually located at the outer end of the tie rod.

- Using an appropriate size wrench or socket, loosen the tie rod end nut by turning it counterclockwise. Note that some tie rod end nuts may have a cotter pin or locking mechanism that needs to be removed before you can access the nut.

- If the nut is stubborn and difficult to remove, you can apply some penetrating oil to help loosen it.

- Once the tie rod end nut is sufficiently loose, you can remove it completely.

- Set the nut aside in a safe place where it won’t get lost.

Removing the tie rod end nut may require some effort, especially if it has been in place for a long time. Be patient and use steady force to avoid damaging the nut or surrounding components. If necessary, you can use a breaker bar or a hammer to provide additional leverage.

Once the tie rod end nut is removed, you can proceed to the next step to separate the tie rod end from the steering knuckle.

Step 4: Separating the Tie Rod End from the Steering Knuckle

After removing the tie rod end nut, the next step is to separate the tie rod end from the steering knuckle. The tie rod end is connected to the steering knuckle with a tapered stud, which can be stubborn to separate. Follow these steps:

- Inspect the tie rod end and locate the small opening or slot on the side of the steering knuckle where the stud enters.

- If necessary, clean the area around the opening to ensure a good grip and prevent debris from interfering with the separation process.

- Using a tie rod end puller tool, position the puller over the opening, ensuring that it fits securely and is centered on the stud.

- Tighten the puller bolt on the tool until it is snug against the steering knuckle.

- Using a wrench, turn the puller bolt counterclockwise to apply pressure on the stud, gradually separating the tie rod end from the steering knuckle.

- Continue turning the puller bolt until the tie rod end pops out of the steering knuckle.

- Once the tie rod end is separated, remove the puller tool.

Note that some tie rod ends may be held in place with a cotter pin or castle nut. If this is the case, you will need to remove the cotter pin or loosen the castle nut before attempting to separate the tie rod end from the steering knuckle.

Separating the tie rod end from the steering knuckle can require some force, especially if it has been in place for a long time. If necessary, you can tap the side of the steering knuckle with a hammer to help loosen the connection.

Once the tie rod end is separated, you can proceed to remove the jam nut in the next step.

Step 5: Removing the Jam Nut

Now that the tie rod end is separated from the steering knuckle, the next step is to remove the jam nut. The jam nut is a smaller nut that locks the tie rod end in place, preventing it from turning during operation. Follow these steps:

- Locate the jam nut on the threaded portion of the tie rod end, closer to the inner end.

- Using an appropriate size wrench, loosen the jam nut by turning it counterclockwise. Depending on the design, you may need to hold the tie rod end with a second wrench to prevent it from rotating while you loosen the jam nut.

- Continue turning the jam nut until it is fully loosened and can be removed by hand.

- Set the jam nut aside in a safe place.

The jam nut is usually tightened against the tie rod end to create a lock and prevent the tie rod end from coming loose. Removing the jam nut allows you to adjust the length of the tie rod during installation or replacement.

Be careful not to damage the threads of the tie rod end or the jam nut while loosening it. If the jam nut is difficult to loosen, you can apply some penetrating oil and tap it lightly with a hammer to help break any corrosion or rust that may be present.

With the jam nut removed, you can now proceed to the next step to remove the old tie rod end.

Step 6: Removing the Tie Rod End

With the jam nut removed, you can now proceed to remove the old tie rod end from the vehicle. The tie rod end is threaded onto the inner end of the tie rod, and it will need to be unscrewed to allow for installation of the new tie rod end. Follow these steps:

- Grab the tie rod end near the outer end and hold it firmly.

- Turn the tie rod end counterclockwise to unscrew it from the inner end of the tie rod.

- Continue unscrewing the tie rod end until it is completely removed from the tie rod.

- Inspect the tie rod end for any visible signs of damage or wear, such as torn boots, loose joints, or excessive play. If the tie rod end is damaged, it should be replaced with a new one.

- Set the old tie rod end aside or discard it, depending on its condition.

Removing the tie rod end may require some effort, especially if it has been in place for a long time. If it is difficult to unscrew, you can use a wrench to provide additional leverage or even tap it gently with a hammer to help break any corrosion or rust that may be present. However, take care not to damage the tie rod or any other surrounding components.

Once the old tie rod end is removed, you can proceed to the next step to install the new tie rod end.

Step 7: Installing the New Tie Rod End

With the old tie rod end removed, it’s time to install the new tie rod end onto the tie rod. This step is crucial for restoring the steering performance of your vehicle. Follow these steps:

- Take the new tie rod end and apply a thin layer of grease to the tapered stud. This will help with installation and ensure smooth operation.

- Align the threaded end of the new tie rod end with the inner end of the tie rod.

- Begin threading the new tie rod end onto the tie rod by turning it clockwise. Make sure it is threaded on straight and engaged properly.

- Continue threading until the new tie rod end is firmly seated against the inner end of the tie rod.

- Using an appropriate size wrench or adjustable wrench, hold the new tie rod end in place to prevent it from rotating while you tighten the jam nut.

- Take the jam nut that was removed earlier and thread it onto the tie rod, tightening it against the new tie rod end. Use a wrench to tighten the jam nut securely.

- Ensure that the new tie rod end is properly aligned and seated on the tie rod. Double-check that the jam nut is tightened enough to hold the new tie rod end in place.

It is important to ensure that the new tie rod end is threaded onto the tie rod securely and aligned properly. Proper alignment will help maintain the integrity of the steering system and prevent any potential issues down the road.

Once the new tie rod end is installed and secured, you can proceed to the next step to reassemble the various components.

Step 8: Reassembling the Components

With the new tie rod end installed, it’s time to reassemble the various components to complete the repair. Follow these steps:

- Ensure that the tie rod end and jam nut are properly tightened and aligned.

- If there was a cotter pin or castle nut securing the tie rod end nut, reinstall it to secure the nut in place. Bend the ends of the cotter pin or properly tighten the castle nut.

- If necessary, apply some grease to the outer end of the tie rod end where it connects to the steering knuckle. This will help with smooth operation and longevity.

- Position the tie rod end back into the steering knuckle.

- Line up the hole on the tie rod end stud with the slot or opening on the steering knuckle.

- Insert a new cotter pin through the hole and bend the ends to secure it in place.

Reassembling the various components requires careful attention to detail. Make sure that all nuts, bolts, and cotter pins are properly tightened and secured. Double-check that the tie rod end is firmly attached to the steering knuckle and there is no excessive play or movement.

Proper alignment and secure reassembly of the components are crucial for the functioning and safety of the steering system. Take your time to ensure that everything is in its place before proceeding to the next step.

With the components reassembled, you’re almost done. The final step is to lower the vehicle and test the repair.

Step 9: Lowering the Vehicle and Testing the Repair

After completing the tie rod end repair, it’s time to lower the vehicle and test the effectiveness of the repair. Follow these steps:

- Remove the jack stands by lifting the vehicle slightly with the jack and carefully removing each stand.

- Once all the stands are removed, slowly lower the vehicle by turning the jack handle counterclockwise.

- Continue lowering the vehicle until all four wheels are back on the ground.

- Use a torque wrench to tighten the lug nuts on the wheel to the manufacturer’s recommended specifications. This will ensure proper wheel installation and prevent any potential issues.

- With the vehicle lowered, start the engine and turn the steering wheel from lock to lock. Listen for any abnormal noises and pay attention to the steering response and stability.

- Take the vehicle for a test drive, preferably on a road with minimal traffic. Pay attention to how the vehicle handles and if there are any vibrations or steering issues.

- If everything feels and sounds normal, congratulations! You’ve successfully repaired the outside tie rod end on your 2006 Dodge Caravan.

During the test drive, be mindful of any changes in the steering feel or performance. If you notice any issues such as excessive play, vibrations, or unusual noises, it is advisable to recheck the installation and potentially seek professional help to ensure the repair was done correctly.

Remember, proper alignment is crucial for the optimal performance of the tie rod end and the steering system as a whole. If you have any doubts or concerns about the repair, it’s always best to consult a professional mechanic.

By following these steps and thoroughly testing the repair, you can have confidence in the improved steering performance and safety of your Dodge Caravan.

Conclusion

Congratulations on successfully completing the repair of the outside tie rod end on your 2006 Dodge Caravan! By following these step-by-step instructions and using the necessary tools, you have taken an important step towards ensuring the optimal functioning of your vehicle’s steering system.

Repairing the tie rod end is a task that requires some mechanical knowledge and patience, but it is a manageable job for most DIY enthusiasts. By replacing the worn or damaged tie rod end, you have improved the steering stability, responsiveness, and overall safety of your vehicle.

Throughout the repair process, it is crucial to emphasize safety. Always use proper jack stands and follow the recommended procedures for jacking up and lowering the vehicle. Additionally, be sure to tighten all nuts and bolts to the manufacturer’s specifications and thoroughly test the repair before resuming normal driving.

If you ever feel unsure or uncomfortable with any aspect of the repair, it is always best to seek professional assistance. Your safety and the safety of others on the road should always be the top priority.

By successfully completing this repair, you have not only saved money but also gained a valuable experience and a sense of accomplishment. With a properly functioning tie rod end, you can enjoy a smoother and more controlled driving experience for many miles to come.

Remember to stay vigilant and perform regular inspections of your vehicle’s suspension and steering components to catch any potential issues early on. By taking care of these maintenance tasks, you can ensure the long-term reliability and performance of your Dodge Caravan.

Safe travels and happy driving!