What Are RFID Tags Made Of

Introduction

When it comes to travel, having the right essentials and accessories can make all the difference. From keeping your belongings organized to ensuring a smooth and comfortable journey, travel essentials play a vital role in enhancing your travel experience. One such essential that has gained popularity over the years is RFID tags.

RFID, which stands for Radio Frequency Identification, is a technology that uses radio waves to wirelessly identify and track objects. RFID tags are small electronic devices that consist of various components, each serving a specific purpose. These tags have become a standard feature in many travel accessories due to their ability to enhance security and convenience.

In this article, we will delve into the basics of RFID tags, their components, and the different types available in the market. We will also explore the various applications of RFID tags in the travel industry. So, whether you’re a frequent traveler or someone planning their next adventure, this article will equip you with the knowledge to make informed choices when it comes to travel essentials and accessories.

Basic components of RFID tags

RFID tags are composed of several key components that work together to enable their functionality. Understanding these components is essential in comprehending how RFID technology works and its applications in various industries, including travel.

Here are the basic components of RFID tags:

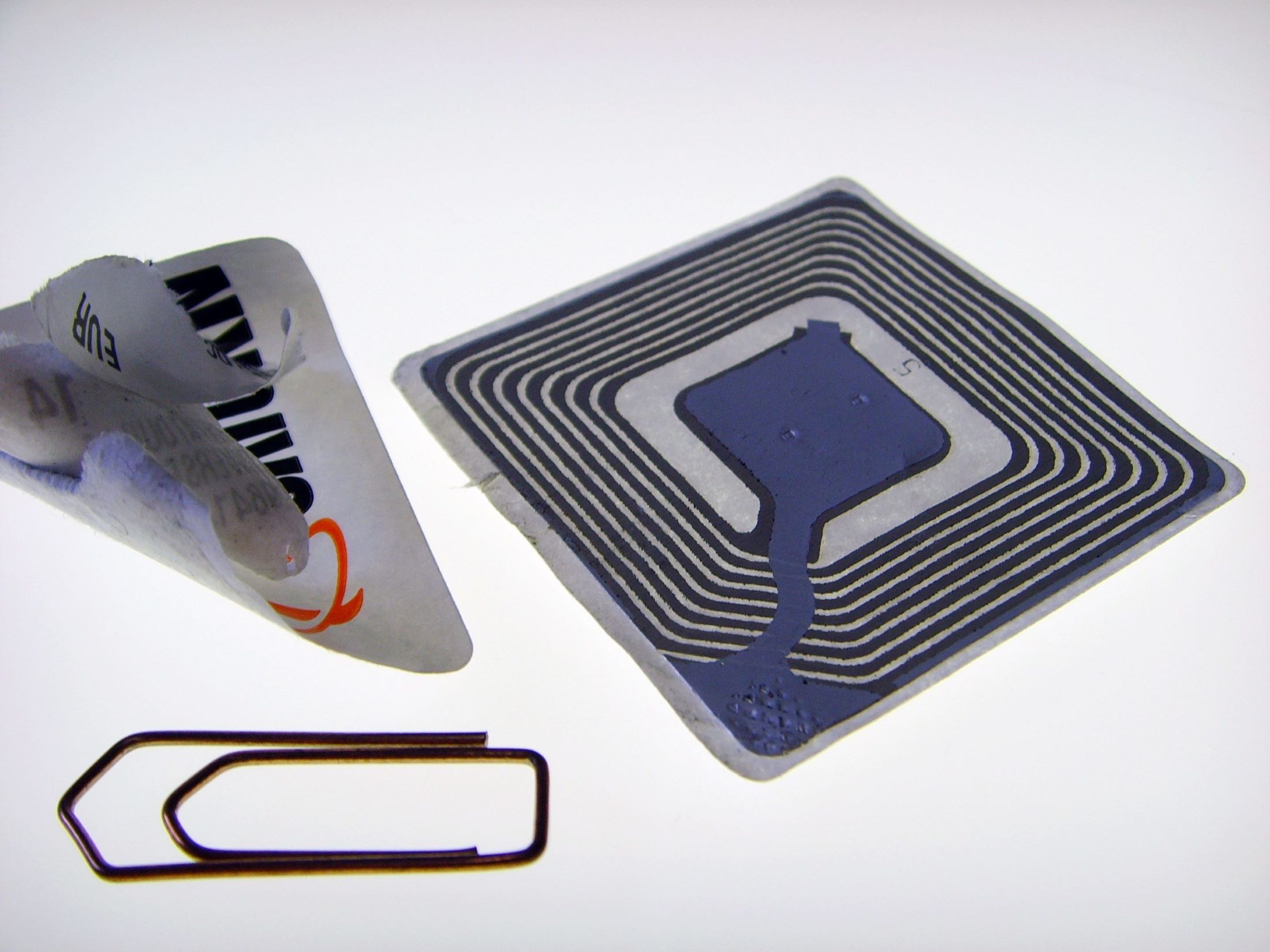

- Antenna: The antenna is responsible for transmitting and receiving radio waves. It acts as a communication bridge between the RFID tag and the RFID reader device. The size and design of the antenna may vary depending on the specific application and desired read range.

- Chip: The chip, also known as an integrated circuit or IC, is the brain of the RFID tag. It stores and processes data, such as the unique identification number of the tag. The chip also contains the necessary logic to communicate with the RFID reader.

- Substrate: The substrate is the material on which the antenna and chip are mounted. It provides support and protection to the delicate components of the RFID tag. Common substrate materials include polyester, paper, or ceramics.

- Housing material: The housing material encloses the internal components of the RFID tag, providing physical protection and durability. It can be made of various materials, such as plastic, metal, or even fabric, depending on the application and environmental conditions.

These components work together to enable the RFID tag to transmit and receive data wirelessly. When an RFID reader emits a radio frequency signal, the tag’s antenna captures the signal and powers the chip. The chip then modulates the signal and sends back the encoded data to the reader, allowing for identification and tracking of the tagged item.

In the next sections, we will explore the different types of RFID tags, including passive, active, and semi-passive tags, and their respective applications in travel essentials and accessories.

Antenna

The antenna is a crucial component of RFID tags as it enables the wireless communication between the tag and the RFID reader. The design and construction of the antenna play a crucial role in determining the tag’s read range and performance.

There are various types of antennas used in RFID tags, depending on the specific application requirements. The most common types of antennas are:

- Wire Antenna: This type of antenna consists of a conductive wire, such as copper or aluminum, formed into a specific pattern. It is cost-effective and suitable for applications that require short to medium ranges. Wire antennas are commonly used in access control, inventory management, and asset tracking systems.

- Printed Antenna: Printed antennas are created using conductive ink or metal traces printed on a substrate, such as a flexible plastic film. They offer versatility in design and can be easily integrated into various forms, including labels, tags, and wearable items. Printed antennas are commonly used in retail, logistics, and healthcare industries.

- Microstrip Antenna: Microstrip antennas are thin, lightweight, and offer excellent performance. They consist of a metal patch mounted on a dielectric substrate, which acts as a ground plane. Microstrip antennas are commonly used in applications that require high read range, such as vehicle tracking, supply chain management, and toll collection systems.

The size and shape of the antenna are also crucial factors in determining the tag’s read range and performance. Generally, larger antennas tend to have a longer read range compared to smaller ones. However, the choice of antenna size should be balanced with the size and form factor of the RFID tag to ensure practicality and usability.

In addition to the physical design, the orientation and placement of the antenna within the RFID tag also impact its performance. Proper antenna placement ensures optimal signal reception and transmission, resulting in reliable and accurate data communication with the RFID reader.

Overall, the antenna is a critical component of RFID tags as it enables the wireless communication between the tag and the RFID reader. By using an appropriate antenna design, RFID tags can achieve longer read ranges and higher performance, making them suitable for various travel essentials and accessories that require efficient tracking and identification.

Chip

The chip, also known as the integrated circuit (IC) or microchip, is the brain of an RFID tag. It contains the necessary components and circuits to store and process data, as well as communicate with the RFID reader. The chip plays a crucial role in enabling the unique identification and tracking capabilities of RFID tags.

RFID chips are available in different variations, and each has specific functionalities and capabilities. Here are some of the key aspects of RFID chips:

- Memory: RFID chips have various memory capacities, ranging from a few kilobytes to multiple megabytes. The memory is used to store data, such as unique identification numbers, product information, or user-defined parameters. The choice of memory capacity depends on the specific application requirements.

- Processing Power: The processing power of the RFID chip determines its ability to handle complex tasks, such as encryption and authentication. Advanced RFID chips may have built-in cryptographic functions to ensure the security and integrity of data transmission.

- Communication Protocol: RFID chips support different communication protocols, such as EPC Gen2, ISO 14443, or NFC (Near Field Communication). The communication protocol determines how the chip interacts with the RFID reader and other devices, ensuring compatibility and interoperability.

- Power Management: The chip may have built-in power management features to optimize power consumption and prolong the battery life for battery-powered RFID tags. These features include sleep mode, wake-on-demand, and energy harvesting capabilities.

The chip interacts with the antenna to receive and transmit data wirelessly. When an RFID reader emits a radio frequency signal, the antenna captures it and powers the chip using electromagnetic induction. The chip then uses the power received to process commands, execute operations, and communicate with the RFID reader.

Additionally, RFID chips can be classified into two main types: read-only and read-write. Read-only chips have a pre-programmed unique identification number and cannot be modified or written with new data. On the other hand, read-write chips allow for read and write operations, enabling dynamic data storage and updates.

The chip’s capabilities and features vary depending on the specific RFID tag’s purpose and application. For travel essentials and accessories, RFID chips are often used to enable functionalities like contactless payment, keyless entry, and baggage tracking, enhancing convenience and security for travelers.

Substrate

The substrate is a vital component of RFID tags that provides support and stability to the antenna and microchip. It acts as a solid base on which the other components are mounted, protecting them from damage and ensuring the longevity of the RFID tag.

RFID tag substrates are typically made from materials that are durable, lightweight, and capable of withstanding various environmental conditions. The choice of substrate material depends on factors such as the intended application, desired tag performance, and cost considerations.

Here are some commonly used substrate materials in RFID tags:

- Polyester: Polyester is a popular substrate material due to its durability and high tensile strength. It is resistant to temperature variations, moisture, and harsh chemicals, making it suitable for outdoor applications. Polyester substrates are commonly used in asset tracking, inventory management, and industrial applications.

- Paper: Paper substrates are lightweight, cost-effective, and easy to print on. They are commonly used in RFID labels and tickets for applications like event management, access control, and product labeling. While paper substrates may not offer the same level of durability as polyester or ceramic, they are suitable for short-term or disposable use.

- Ceramic: Ceramic substrates provide excellent performance and durability. They offer high thermal stability, resistance to chemical substances, and are capable of withstanding extreme conditions. Ceramic substrates are often used in harsh environments or applications that require long-term durability, such as automotive tracking and industrial manufacturing.

The substrate may also incorporate additional features to enhance the overall functionality of the RFID tag. For example, some substrates have adhesive backing, allowing for easy attachment to objects or surfaces. Others may have special coatings to provide protection against abrasion, UV radiation, or water damage.

In addition to providing structural support, the substrate also plays a role in determining the flexibility or rigidity of the RFID tag. Flexible substrates, such as polyester or certain polymers, allow for the creation of bendable and conformable RFID tags, making them suitable for applications like wearable devices and curved surfaces.

Overall, the choice of substrate material depends on the specific requirements of the RFID tag, including durability, environmental conditions, flexibility, and cost considerations. By selecting the appropriate substrate, RFID tags can maintain their integrity and ensure reliable performance, even in challenging travel environments.

Housing Material

The housing material of an RFID tag refers to the outer covering that encloses the internal components, providing physical protection and durability. The choice of housing material depends on factors such as the tag’s intended application, environmental conditions, and desired aesthetics.

Here are some commonly used housing materials for RFID tags:

- Plastic: Plastic is a widely used housing material due to its versatility, durability, and cost-effectiveness. It can be molded into various shapes and sizes, making it suitable for a wide range of tag designs. Plastic housings provide good protection against moisture, temperature variations, and impact. They are commonly used in applications such as access control cards, key fobs, and luggage tags.

- Metal: Metal housings offer enhanced durability and ruggedness, making them suitable for applications that require resistance to harsh environments, rough handling, or extreme temperatures. Metal housings can be made from materials like stainless steel or aluminum alloy. They are commonly used in industrial, automotive, and outdoor tracking applications where durability is paramount.

- Fabric: Fabric housings are designed for flexibility and comfort. They are commonly used for RFID wristbands, key rings, and wearable accessories. Fabric housings are typically made from materials like nylon, polyester, or silicone. They provide a soft and comfortable feel, making them ideal for applications that require prolonged contact with the skin, such as health and fitness tracking.

In addition to the material, the housing may incorporate additional features or components to enhance the functionality of the RFID tag. For example, it may include a slot or pocket to hold a paper or plastic card for identification purposes. The housing may also have a lanyard or strap attachment point for easy carrying or attachment to objects.

The choice of housing material is crucial as it affects the durability, reliability, and aesthetics of the RFID tag. It is important to consider factors such as the tag’s intended application, environmental conditions, and user preferences when selecting the housing material. By choosing the appropriate housing material, RFID tags can withstand the rigors of travel and ensure long-lasting performance.

Types of RFID Tags

RFID tags come in various types, each offering unique features and functionalities. The different types of RFID tags can be classified based on their power source and operating capabilities. The three main types of RFID tags are passive, active, and semi-passive tags.

- Passive RFID Tags: Passive RFID tags do not have an internal power source. They rely on the energy emitted by the RFID reader to power the tag and enable communication. When the reader emits a radio frequency signal, the tag’s antenna captures the energy and uses it to transmit data back to the reader. Passive tags are cost-effective and widely used in applications like inventory management, access control, and retail merchandise tagging. However, their read range is relatively short and depends on the power emitted by the reader.

- Active RFID Tags: Active RFID tags have their own internal power source, typically a battery. The battery powers the tag’s circuitry, including the chip and the antenna. Active tags can emit a stronger signal and have a longer read range compared to passive tags. They are suitable for applications that require real-time tracking, such as vehicle tracking, asset management, and high-value item tracking. Active tags are more expensive than passive tags and have a limited battery life that requires periodic replacement or recharging.

- Semi-Passive RFID Tags: Semi-passive RFID tags, also known as battery-assisted passive (BAP) tags, combine features of both passive and active tags. They have an internal power source that powers the chip and other circuitry, while relying on the reader for communication. The battery in semi-passive tags extends their read range and enhances their response time compared to passive tags. Semi-passive tags are commonly used in applications like temperature monitoring, logistics, and supply chain management.

The choice of RFID tag type depends on the specific requirements of the application. Passive tags are suitable for simple tracking and identification purposes where cost-effectiveness is important. Active tags are used for real-time tracking and monitoring applications where longer read ranges are required. Semi-passive tags offer a balance between cost and performance.

It’s important to note that each RFID tag type has its own advantages and disadvantages, so it’s crucial to consider the specific needs of the application and weigh the benefits accordingly. By understanding the different types of RFID tags, one can make an informed decision when choosing the most suitable tag for their travel essentials and accessories.

Passive RFID Tags

Passive RFID tags are a popular and widely used type of RFID tag that operates without an internal power source. Instead, they rely on the energy emitted by the RFID reader to power their operations. Passive RFID tags are cost-effective, lightweight, and compact, making them suitable for a wide range of applications in the travel industry.

Here are some key features and characteristics of passive RFID tags:

- Power Source: Passive RFID tags do not have a built-in power source or battery. They derive power from the radio frequency energy transmitted by the RFID reader when the tag is within the vicinity of the reader’s electromagnetic field.

- Read Range: The read range of passive RFID tags typically ranges from a few centimeters up to a few meters, depending on the power emitted by the reader. The read range can be extended by using larger antennas or higher-powered RFID readers.

- Cost-Effectiveness: Passive RFID tags are more cost-effective compared to active or semi-passive tags. Their simple design and lack of internal power source contribute to their affordability, making them ideal for applications where large quantities of tags are required.

- Size and Form Factors: Passive tags come in various sizes and form factors to suit different applications. They can be as small as a grain of rice or as large as a credit card. Passive tags can be embedded in labels, stickers, key fobs, or be integrated into other travel accessories, such as luggage tags and passports.

- Multiple Tags Simultaneous Reading: Passive RFID technology allows for the simultaneous reading of multiple tags within the reader’s range. This makes it convenient for inventory management, asset tracking, and other applications that involve reading multiple items at once.

- Application: Passive RFID tags find extensive use in various travel-related applications, including baggage tracking, access control, ticketing, and retail inventory management. They are cost-effective solutions for enhancing efficiency, security, and customer experience in the travel industry.

Passive RFID tags offer a reliable and cost-effective solution for tracking and identifying objects in travel essentials and accessories. Their simplicity, compact size, and ability to operate without an internal power source make them versatile and suitable for a wide range of applications. Whether it’s tracking luggage, managing inventory, or streamlining access control, passive RFID tags are an essential component in enhancing operational efficiency and improving the overall travel experience.

Active RFID Tags

Active RFID tags are a type of RFID tag that differ from passive tags in that they have their own internal power source, typically in the form of a battery. This power source allows active tags to independently emit a radio frequency signal, making them capable of longer read ranges and enabling real-time tracking and monitoring capabilities.

Here are some key features of active RFID tags:

- Power Source: Active RFID tags are powered by an internal battery, which provides the necessary energy for tag operations. The battery allows active tags to emit a strong signal consistently, enabling longer read ranges compared to passive tags.

- Read Range: Active RFID tags can have a significantly longer read range compared to passive tags, typically extending up to several hundred meters. The increased read range makes active tags suitable for applications that require tracking objects over large distances, such as vehicle tracking or warehouse management.

- Real-Time Monitoring: The independent power source in active tags enables them to transmit data continuously, allowing for real-time monitoring and tracking. This makes active tags valuable in applications that require live updates and instant visibility of tagged assets or personnel.

- Higher Cost: Active RFID tags are generally more expensive than passive tags due to their additional components, including the battery. The cost of the battery and the need for periodic battery replacement or recharging contribute to the higher upfront investment of active tags.

- Size and Form Factors: Active RFID tags come in various sizes and form factors, ranging from small, compact devices to larger and ruggedized tags. Their size and form factor depend on the specific application requirements, whether it’s attaching them to assets, vehicles, or personnel.

- Application: Active RFID tags are commonly used in applications that require real-time tracking and monitoring. They are utilized in industries such as logistics, transportation, construction, and healthcare for asset management, personnel tracking, and supply chain optimization.

The use of active RFID tags enables enhanced visibility, security, and efficiency in various travel-related scenarios. For example, in airport operations, active tags can help track and manage ground support equipment, monitor the location of baggage carts, and improve passenger flow through automated gate systems. Active tags are also valuable for tracking high-value assets in the hospitality industry or managing access control in secure areas.

While active RFID tags require a higher initial investment compared to passive tags, their extended read range and real-time monitoring capabilities make them indispensable in applications that demand accurate location tracking and timely data acquisition.

Semi-Passive RFID Tags

Semi-passive RFID tags, also known as battery-assisted passive (BAP) tags, combine features of both passive and active RFID tags. These tags have an internal power source, typically a battery, which powers the tag’s circuitry while relying on the RFID reader for communication. Semi-passive tags offer a balance between the cost-effectiveness of passive tags and the extended read range of active tags.

Here are some key features of semi-passive RFID tags:

- Power Source: Semi-passive RFID tags have an internal power source, usually a small battery. The battery powers the tag’s chip and enables additional functionalities, such as increasing the read range or enhancing response times.

- Read Range: The read range of semi-passive tags can be extended compared to passive tags, thanks to the battery-powered chip. They can achieve a read range similar to active tags while offering better battery life. The read range can vary based on factors such as battery capacity, tag design, and reader power.

- Enhanced Performance: The battery assistance in semi-passive tags enhances their performance in terms of response time and signal transmission. This makes them suitable for applications that require faster tag identification and real-time data capture.

- Battery Life: The battery life of semi-passive tags can vary depending on the usage and power requirements. The battery can last for months or even years, depending on factors like the frequency of tag activation and the power consumption of the tag’s circuitry.

- Cost Considerations: Semi-passive tags are often more expensive than passive tags due to the inclusion of a battery, but they are generally more cost-effective than active tags. The cost of the battery and the additional functionalities are balanced with the improved performance and extended read range.

- Application: Semi-passive RFID tags find applications in various industries where extended read range and optimized power consumption are required. They are used in asset tracking, supply chain management, temperature monitoring, and other applications that benefit from the advantages offered by their hybrid functionality.

Semi-passive RFID tags strike a balance between the extended read range of active tags and the cost-effectiveness of passive tags. The battery assistance allows them to overcome the limitations of passive tags, providing improved performance and better reliability in applications where longer read ranges and faster response times are necessary.

Common use cases for semi-passive RFID tags include tracking high-value assets in logistics, monitoring the temperature of perishable goods during transportation, and optimizing inventory management in retail settings. The semi-passive design makes these tags versatile and adaptable, suitable for a wide range of travel essentials and accessories.

Applications of RFID Tags

RFID tags have numerous applications in the travel industry, offering benefits such as improved efficiency, enhanced security, and seamless customer experiences. Let’s explore some of the key applications of RFID tags:

- Baggage Tracking: RFID tags are used to track and trace luggage throughout the travel journey. By attaching RFID tags to bags, airports and airlines can monitor their movement, ensuring accurate routing, reducing the risk of lost baggage, and enhancing overall passenger satisfaction.

- Access Control: RFID tags are employed in access control systems for secure identification and authentication. They can be integrated into key cards or wearable devices, enabling contactless entry to hotel rooms, restricted areas, and transportation facilities.

- Inventory Management: RFID tags revolutionize inventory management in various industries, including retail and hospitality. By tagging products or assets with RFID tags, businesses gain real-time visibility of their inventory, automate stock counting, prevent theft, and improve stock replenishment processes.

- Ticketing and Passes: RFID technology is used in ticketing systems for events, public transportation, and theme parks. RFID-enabled tickets or passes facilitate fast and hassle-free access, reducing queues and enhancing the overall visitor experience.

- Smart Retail: RFID tags enable smart retail solutions, including automated checkout systems and real-time inventory tracking. By tagging merchandise, retailers can streamline the shopping experience, reduce inventory inaccuracies, and offer personalized recommendations to customers.

- Asset Tracking: RFID tags are valuable for tracking and managing assets such as equipment, tools, and vehicles. By attaching RFID tags to assets, businesses can monitor their location, utilization, and maintenance requirements, improving asset visibility and operational efficiency.

- Healthcare Management: RFID tags are used in healthcare for patient tracking, asset management, and medication administration. They help improve patient safety, streamline workflow processes, and ensure the availability of critical medical supplies and equipment.

- Supply Chain Optimization: RFID tags play a vital role in optimizing supply chain management. They provide real-time visibility of goods, enable accurate inventory control, minimize stockouts, and enhance supply chain transparency and traceability.

These are just a few examples of the broad range of applications where RFID tags make a significant impact. The versatility, accuracy, and efficiency of RFID technology have transformed various aspects of the travel industry, ensuring smoother operations, improving customer satisfaction, and enabling organizations to make data-driven decisions.

As technology continues to evolve, we can expect RFID tags to be integrated into even more travel essentials and accessories, providing innovative solutions that enhance comfort, convenience, and safety for travelers worldwide.

Conclusion

RFID tags have revolutionized the travel industry, providing a range of benefits from enhanced security to improved operational efficiency. Understanding the basic components of RFID tags, including the antenna, chip, substrate, and housing material, is essential to appreciate their functionality and application in travel essentials and accessories.

Passive RFID tags, powered by the energy emitted by RFID readers, offer a cost-effective solution for tracking and identifying objects. They find applications in baggage tracking, access control, inventory management, and more. Active RFID tags, with their internal power source, provide longer read ranges and real-time tracking capabilities. They are commonly used in applications such as vehicle tracking and asset management. Semi-passive RFID tags strike a balance between passive and active tags, offering extended read ranges and optimized power consumption.

The applications of RFID tags in the travel industry are diverse and impactful. From baggage tracking to access control, inventory management to smart retail, RFID tags enable improved efficiency, enhanced security, and seamless customer experiences. They play a vital role in optimizing supply chain management, offering real-time visibility, accuracy, and traceability of goods.

As the travel industry continues to evolve, RFID technology will undoubtedly play a crucial role in shaping the future of travel essentials and accessories. From ensuring the safe and timely delivery of luggage to providing contactless access to hotel rooms, RFID tags are at the forefront of enhancing travel experiences.

In conclusion, RFID tags offer a powerful tool for improving various aspects of the travel industry. As technology advances and costs decrease, we can expect RFID tags to become even more pervasive, providing innovative solutions that streamline operations, enhance security, and elevate the overall travel experience for individuals and businesses alike.