How Does RFID Reader Work

Introduction

Welcome to the fascinating world of RFID technology! In today’s fast-paced society, where efficiency and convenience are highly valued, RFID technology has become an essential part of our daily lives. Whether it’s managing inventory in a retail store, streamlining the flow of goods in a supply chain, or ensuring secure access to restricted areas, RFID readers play a vital role in enabling these processes.

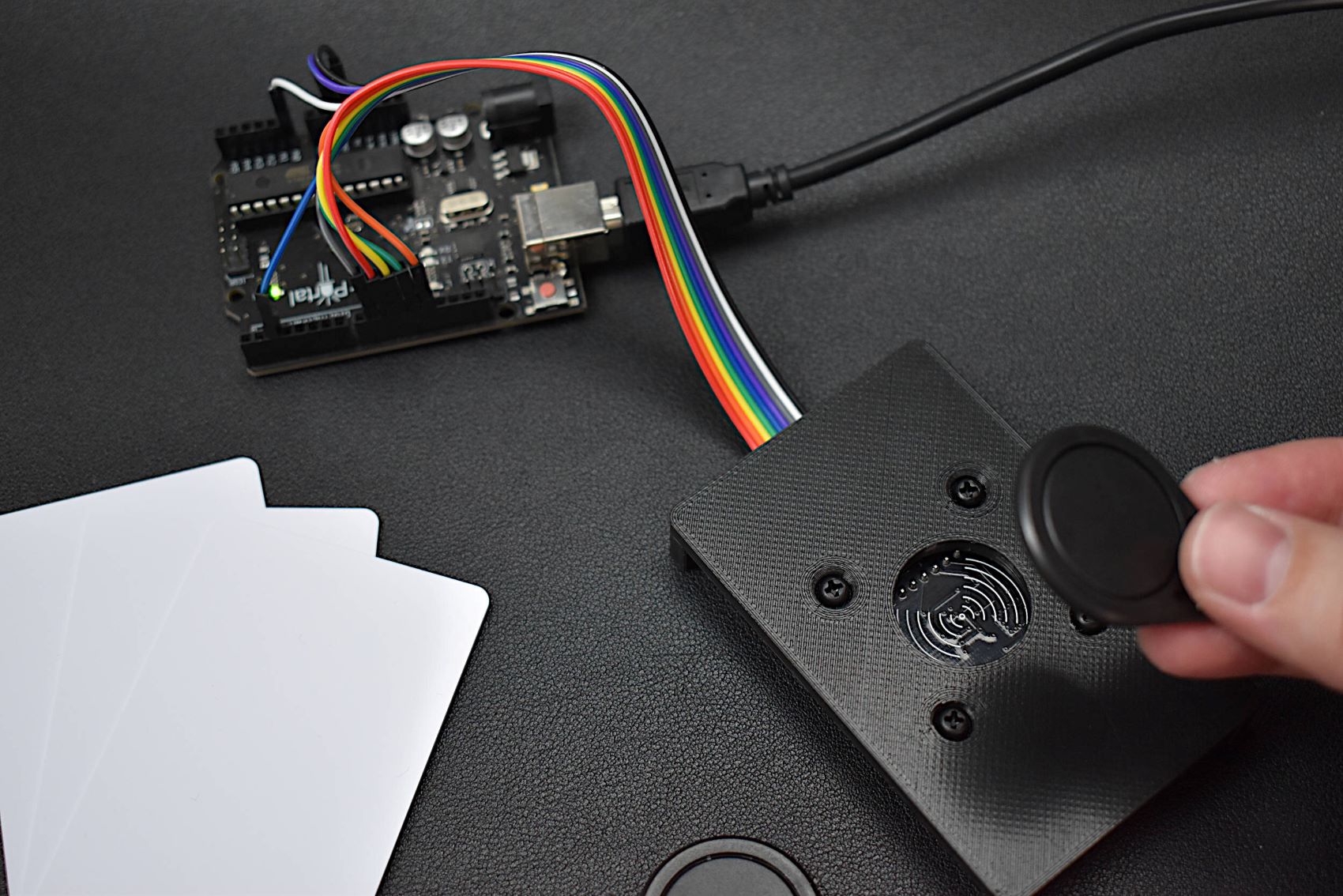

RFD, which stands for Radio Frequency Identification, refers to a wireless technology that uses electromagnetic fields to automatically identify and track objects or individuals. The technology consists of two main components – tags and readers. While RFID tags are affixed to the objects or people being tracked, RFID readers are responsible for detecting and collecting the information stored in the tags.

So, how exactly does an RFID reader work? In this article, we will delve into the basics of RFID technology and explore the inner workings of an RFID reader. We will discuss the different components that make up an RFID reader and their functions. Additionally, we will also explore the various frequencies at which RFID readers operate and examine the applications of RFID technology in different industries.

By the end of this article, you will have a comprehensive understanding of how RFID readers function and their significance in various sectors. So, let’s jump right in and unravel the intricacies of RFID technology!

Basics of RFID Technology

Before we dive into the intricacies of RFID readers, let’s grasp the fundamental principles of RFID technology. At its core, RFID technology utilizes radio waves to communicate and transmit data between RFID tags and readers. These tags, often referred to as transponders, contain an integrated circuit and an antenna that enable them to transmit and receive information.

RFID tags come in various forms, ranging from passive to active. Passive RFID tags do not have their own power source and instead rely on the energy emitted by the RFID reader to activate and transmit data. On the other hand, active RFID tags have their own power source, allowing them to transmit data over greater distances.

When an RFID reader emits radio frequency waves, it creates an electromagnetic field. When an RFID tag enters this field, it absorbs some of the energy from the waves, which in turn powers up the tag. Once activated, the RFID tag is capable of transmitting its unique identifier and other relevant data to the reader.

The communication between the RFID reader and the tag occurs through a process known as backscatter. This process involves the tag modulating its antenna to reflect a portion of the incoming RF signal. The reflected signal contains the encoded information, which the reader decodes and processes.

It’s important to note that RFID technology operates over different frequencies, with each frequency band serving specific purposes. Low Frequency (LF) RFID operates at frequencies of 30 kHz to 300 kHz and is often used for access control systems. High Frequency (HF) RFID operates at frequencies of 3 MHz to 30 MHz and finds applications in areas such as inventory management and supply chain tracking. Ultra High Frequency (UHF) RFID operates at frequencies of 300 MHz to 3 GHz and is commonly used in industries like retail and asset tracking.

Now that we have a grasp of the basic principles of RFID technology, let’s take a closer look at the components that make up an RFID reader and their roles in facilitating this communication process.

Components of an RFID Reader

An RFID reader is a complex device that consists of several key components working together to facilitate the communication and data transfer process between the reader and RFID tags. Let’s explore the main components of an RFID reader and their respective functions:

- Antenna: The antenna is a crucial component that emits and receives radio frequency signals. It generates the electromagnetic field necessary to power up the RFID tags and capture the data transmitted by them. Antennas come in various shapes and sizes, depending on the application and frequency of operation.

- Transceiver: The transceiver, also known as the reader module, is responsible for transmitting and receiving RF signals. It converts the electrical signals from the antenna into radio frequency waves and vice versa. Additionally, the transceiver amplifies weak signals from the tags and filters out unwanted noise, ensuring reliable communication between the reader and the tags.

- Controller: The controller acts as the brain of the RFID reader. It processes the data received from the transceiver, performs necessary computations or validations, and manages the overall functioning of the reader. The controller may also include a microprocessor, memory, and firmware to execute specific tasks and support various protocols.

- Power Source: RFID readers require a power source to operate. Depending on the application, readers can be powered through a variety of sources, such as AC power or batteries. The power source supplies the necessary electrical energy to the reader, ensuring continuous operation for extended periods.

These components work in harmony to enable the RFID reader to communicate with RFID tags in its vicinity. The antenna creates the necessary electromagnetic field, the transceiver transmits and receives RF signals, the controller processes the data, and the power source sustains the reader’s power requirements.

It’s important to note that RFID readers can come in various forms, including handheld devices, fixed readers, or even integrated within other devices like smartphones or tablets. The specific components and their configurations may vary depending on the reader’s design, application, and frequency of operation.

Now that we have a clear understanding of the components that make up an RFID reader, let’s explore how these components work together during the operation of an RFID reader in the next section.

Antenna

The antenna is a vital component of an RFID reader, responsible for emitting and receiving radio frequency signals. It plays a crucial role in establishing communication between the reader and RFID tags. The antenna generates an electromagnetic field that powers up the RFID tags and allows for the transmission and reception of data.

RFID reader antennas come in various shapes and sizes, each serving different purposes depending on the application and frequency of operation. The shape of an antenna can range from linear to circular, or even custom-designed for specific purposes. Additionally, the size of the antenna is determined by factors such as the desired read range, the environment in which it will be used, and the type of tags it will communicate with.

Antennas for RFID readers are designed to radiate electromagnetic waves efficiently and detect the signals reflected back from the RFID tags. The two main types of antenna polarization used in RFID applications are linear and circular polarization.

Linear polarization: Linearly polarized antennas emit radio waves in a specific orientation, either vertically or horizontally. They are commonly used in applications where the orientation of the tag is known, and the antenna can be aligned to maximize signal strength.

Circular polarization: Circularly polarized antennas emit radio waves in a circular motion, allowing for a more flexible tag orientation. These antennas are commonly used in applications where the tag’s orientation may vary, such as in retail settings or environments with moving objects.

In addition to polarization, another important characteristic of RFID antennas is gain. Antenna gain determines the direction and concentration of the radiated energy. Higher gain antennas provide a more focused and stronger signal, resulting in an increased read range. However, it is important to strike a balance as using antennas with excessive gain can lead to reader saturation or interference issues.

It’s worth noting that antennas are capable of both powering up RFID tags and collecting the data transmitted by them. When an RFID tag enters the range of the antenna’s electromagnetic field, it absorbs energy from the radio waves emitted by the antenna, which then powers up the tag for communication. Once the tag is powered up, it uses the same antenna to backscatter its unique identifier and relevant data back to the reader for processing.

Overall, the antenna is a critical component of an RFID reader as it enables the reader to communicate with RFID tags. Its design, polarization, and gain all play significant roles in determining the efficiency and effectiveness of the RFID reader in reading tags accurately and reliably.

Transceiver

The transceiver, also known as the reader module, is an essential component of an RFID reader. It plays a crucial role in transmitting and receiving radio frequency signals between the reader and the RFID tags. The transceiver acts as a bridge, converting electrical signals into radio frequency waves and vice versa.

The main function of the transceiver is to amplify and modulate the signals. It receives the weak signals backscattered by the RFID tags and amplifies them to a level that can be processed by the reader. Additionally, the transceiver filters out any unwanted noise or interference that may affect the communication between the reader and tags, ensuring reliable data transmission.

Transceivers come in different forms, depending on the frequency of operation and the specific requirements of the RFID system. They are designed to support various protocols and standards and may incorporate features such as frequency hopping or collision avoidance mechanisms to optimize performance.

Furthermore, the transceiver often includes a microprocessor and firmware that facilitate the execution of specific tasks and handle communication protocols. This allows the reader to interact with the tag, exchange data, and perform necessary operations such as encoding, decoding, or authentication.

The functionality and capabilities of the transceiver can vary depending on the application and the complexity of the RFID system. For example, high-frequency (HF) transceivers used in access control systems may have different features compared to ultra-high-frequency (UHF) transceivers used in supply chain management.

It’s worth mentioning that the transceiver also determines the read range of the RFID reader. The power output and sensitivity of the transceiver play a crucial role in determining how far the reader can detect and communicate with RFID tags. Antenna design, power transmission levels, and regulatory considerations can all affect the performance of the transceiver and influence the read range of the RFID reader.

In summary, the transceiver is a vital component of an RFID reader that facilitates the communication between the reader and RFID tags. Its ability to transmit and receive radio frequency signals, along with its filtering capabilities, amplification, and protocol support, enable the reader to exchange data with the tags efficiently and accurately.

Controller

The controller is the brain of an RFID reader, responsible for managing and coordinating the overall operation of the reader. It plays a crucial role in processing the data received from the transceiver, executing specific tasks, and ensuring the smooth functioning of the RFID system.

At the heart of the controller is a microprocessor or microcontroller, which acts as the central processing unit. The microprocessor receives the data from the transceiver and performs essential computations, such as decoding the information transmitted by the tags, validating the data, or executing specific commands.

In addition to the microprocessor, the controller may also include memory components such as RAM and ROM. RAM is used for temporary data storage, allowing the controller to process and manipulate the data efficiently. ROM contains firmware or software that controls the reader’s operation, handles communication protocols, and supports various functionalities.

The controller is responsible for managing the communication between the reader and the RFID tags. It establishes and maintains the connection, exchanges data, and ensures that the communication follows the appropriate standards and protocols. The controller also handles error detection and correction mechanisms to ensure data integrity.

Furthermore, the controller may have input/output interfaces that allow it to interact with other devices or systems. This can include interfaces such as USB, Ethernet, or serial ports, which enable the reader to connect to a computer or network for data exchange or integration purposes.

Depending on the complexity of the RFID system, the controller may also support additional features and functionalities. These can include encryption and security mechanisms to protect data, device management capabilities for configuration and control, or even integration with other sensors or devices to enhance the reader’s capabilities.

It’s important to note that the controller plays a significant role in the overall performance and adaptability of the RFID reader. The efficiency of the microprocessor, the available memory resources, and the flexibility of the firmware significantly impact the reader’s ability to handle large volumes of data, support various protocols, and execute specific tasks.

In summary, the controller is a vital component of an RFID reader that acts as the control center, overseeing the reader’s operation. Through its microprocessor, memory, and firmware, the controller processes data, manages communication, and supports additional functionalities, ensuring the seamless functioning of the RFID system.

Power Source

The power source is a crucial component of an RFID reader, providing the electrical energy required for the reader to function effectively. RFID readers can be powered through various means, depending on the specific application and requirements.

There are two main types of power sources commonly used for RFID readers:

- AC Power: Many fixed or stationary RFID readers are connected to an alternating current (AC) power source. This power source can be obtained from a wall socket or an external power supply. AC power offers a stable and continuous supply of energy, ensuring uninterrupted operation of the reader.

- Battery Power: Portable or handheld RFID readers are often powered by batteries. These batteries can be rechargeable or disposable, depending on the reader’s design and usage requirements. Battery-powered RFID readers offer flexibility and mobility, allowing them to be used in various environments where access to AC power may be limited or impractical.

The choice of power source depends on several factors, including the reader’s intended application, mobility requirements, and the availability of power sources in the environment where the reader is being used.

It’s worth noting that the power source must provide adequate power to drive the various components of the RFID reader, including the transceiver, controller, and antenna. Insufficient power can lead to reduced performance, limited read range, or even system malfunctions. Therefore, it’s essential to choose a power source that can meet the power requirements of the reader.

In addition to the primary power source, some RFID readers also incorporate power-saving mechanisms to optimize energy consumption. These mechanisms may include sleep modes or power management features that reduce power consumption when the reader is not actively reading or transmitting data. Such features help prolong battery life in portable readers and contribute to overall energy efficiency.

Overall, the power source is a critical component of an RFID reader, providing the necessary electrical energy for its operation. Whether it’s through AC power or batteries, selecting the right power source ensures reliable and continuous functioning of the reader in various applications and environments.

RFID Reader Operation

The operation of an RFID reader involves several key steps that allow it to detect, collect, and process data from RFID tags. Understanding the process is crucial in comprehending the functionality of RFID readers in various applications.

1. Scanning and Detection: When an RFID reader is powered on, it initiates the scanning process by emitting radio frequency waves through its antenna. These waves create an electromagnetic field around the reader. When an RFID tag enters the range of this field, it absorbs some of the energy from the waves, which powers up the tag. 2. Data Collection and Transmission: Once the RFID tag is powered up, it begins to communicate with the reader. In passive RFID systems, the tag uses the energy it received from the reader to modulate its antenna and reflect a portion of the incoming RF signal. The reflected signal contains the encoded data stored in the tag’s memory, such as the unique identifier or product information. The reader’s antenna captures the reflected signal, and the transceiver converts it into electrical signals. 3. Data Processing: The electrical signals received by the transceiver are forwarded to the controller for processing. The controller decodes the information encoded in the received signals, validates the data, and executes specific tasks based on the application requirements. This can include validating access rights, updating inventory records, or triggering actions based on the received data. 4. Output and Interaction: Once the data is processed, the RFID reader can provide output or interact with other devices or systems. This can include displaying the read information on a screen, transmitting data to a computer or network, triggering alarms or notifications, or activating other devices based on the received data. 5. Continual Scanning: RFID readers are designed to continually scan for nearby RFID tags as long as they are powered on. This allows for real-time tracking and monitoring of tagged objects or individuals within the reader’s range. It’s important to note that the operation of an RFID reader can vary depending on the specific application and the frequency band at which it operates. For example, access control systems may involve additional authentication steps, while inventory management systems may involve simultaneous reading of multiple tags for efficient tracking. The effectiveness and efficiency of an RFID reader’s operation depend on factors such as the read range, the power output, the antenna design, the sensitivity of the transceiver, and the processing capabilities of the controller. Optimizing these factors ensures accurate and reliable data collection, ultimately enhancing the performance of the RFID system. Overall, understanding the operation of an RFID reader provides a foundation for grasping its functionality and its role in various applications such as access control, inventory management, supply chain tracking, and more.

Scanning and Detection

Scanning and detection are essential steps in the operation of an RFID reader. This process allows the reader to identify and communicate with RFID tags within its range. Let’s dive deeper into how scanning and detection work in RFID systems.

When an RFID reader is powered on, it emits radio frequency (RF) waves through its antenna, creating an electromagnetic field around it. This field serves as the medium for communication between the reader and RFID tags. As the waves propagate, they energize any RFID tags within their range.

Passive RFID tags, which are the most common type of tags in use today, do not have their own power source. Instead, they rely on the energy harvested from the RF waves emitted by the reader to power up and communicate. When a passive RFID tag enters the range of the reader’s electromagnetic field, it absorbs a portion of the energy transmitted by the reader.

As the passive RFID tag absorbs energy, it becomes energized and starts to respond. The response is typically in the form of backscattering, which means the tag modulates its antenna to reflect a portion of the incoming RF signal. The reflected signal carries the encoded information stored in the tag’s memory, such as a unique identifier or product details.

The reader’s antenna captures the reflected signal, which contains the modulated information from the tag. The antenna then feeds the captured signal to the transceiver, which converts it into electrical signals that can be processed by the RFID reader’s controller.

During the scanning and detection process, the RFID reader’s antenna range defines the area within which it can detect and communicate with RFID tags. The read range can vary depending on factors such as the antenna design, power output of the reader, and environmental conditions.

It is important to note that the scanning and detection process occurs continuously as long as the RFID reader is powered on. This feature allows for real-time tracking, monitoring, and information retrieval from RFID-tagged objects or individuals within the reader’s range.

In summary, scanning and detection are fundamental steps in an RFID reader’s operation. The reader emits RF waves, energizing passive RFID tags within its range. When a tag absorbs the energy, it responds by backscattering a portion of the RF signal back to the reader. The reader’s antenna captures the reflected signal, which is then processed to extract the encoded information from the tag. This process enables the reader to identify and communicate with RFID tags, forming the foundation for various RFID applications such as access control, inventory management, and supply chain tracking.

Data Collection and Transmission

Data collection and transmission are critical processes in the operation of an RFID reader. Once an RFID tag is detected within the reader’s range, the reader collects the encoded data from the tag and transmits it for further processing. Let’s explore how data collection and transmission work in RFID systems.

After the RFID reader’s antenna captures the reflected signal from the RFID tag, the transceiver converts the analog signal into digital data that can be processed by the reader’s controller. This data typically includes the unique identifier of the tag and any additional information encoded in the tag’s memory, such as product details, authentication codes, or timestamps.

The controller of the RFID reader receives the digital data from the transceiver and performs several tasks to process and utilize the collected information. These tasks may involve decoding the data, validating its integrity, and executing specific actions based on the application’s requirements.

Once the data is processed, the RFID reader can transmit it for further integration, analysis, or display. The transmission can take various forms depending on the reader’s design and connectivity options. These options may include wired or wireless connections such as USB, Ethernet, Bluetooth, or Wi-Fi, allowing the reader to interface with other devices or systems.

In the case of handheld or portable RFID readers, the collected data can be transmitted wirelessly to a computer or network for real-time data processing and storage. This enables seamless integration with existing systems and enhances workflow efficiency.

For fixed or stationary RFID readers, the collected data may be directly sent to a centralized system or database for further analysis, updating inventory records, or triggering relevant actions. This enables real-time tracking and monitoring of tagged items or individuals, providing valuable insights for applications such as inventory management, asset tracking, or access control.

It’s worth noting that the data transmission process may involve security measures to protect the collected data from unauthorized access or tampering. Encryption techniques and secure communication protocols can be implemented to ensure data privacy and integrity during transmission.

Overall, data collection and transmission are pivotal functions of an RFID reader. The reader captures and processes data from the detected RFID tags, and then transmits it for further integration, analysis, or display. This seamless process enables real-time tracking, enhances data visibility, and supports a wide range of RFID applications in diverse industries.

RFID Reader Frequencies

RFID technology operates at different frequencies, with each frequency band offering specific benefits and suitability for various applications. The choice of frequency depends on factors such as the read range requirements, the environment, and the types of objects or tags being tracked. Let’s explore the main frequencies at which RFID readers operate:

- Low Frequency (LF): LF RFID operates at frequencies between 30 kHz and 300 kHz. LF tags and readers are commonly used in applications that require close proximity tracking, such as access control systems, animal identification, and keyless entry. LF technology offers a shorter read range compared to other frequencies, but it provides better performance in environments with interference from metals or liquids.

- High Frequency (HF): HF RFID operates at frequencies between 3 MHz and 30 MHz. HF tags and readers are widely used in applications such as contactless payment systems, public transportation cards, and library book tracking. HF technology offers a moderate read range and provides better resistance to interference compared to LF. It is also well-suited for applications that require data transfer at a relatively high speed.

- Ultra High Frequency (UHF): UHF RFID operates at frequencies between 300 MHz and 3 GHz. UHF tags and readers are extensively used in applications such as inventory management, supply chain tracking, and retail operations. UHF technology offers a longer read range, high data transfer rates, and the ability to handle multiple tags simultaneously. It is commonly used for large-scale RFID deployments due to its cost-effectiveness and scalability.

Each frequency band has its advantages and limitations. LF has higher immunity to interference, but it has a shorter range and slower data transfer rates. HF provides moderate range and data transfer rates, while UHF offers longer-range and high-speed data transfer capabilities. The choice of frequency depends on the specific requirements of the application and the environment in which it will be deployed.

It’s important to note that different countries may regulate the frequency bands used for RFID systems. For instance, LF and HF frequency bands are globally harmonized, while UHF bands vary among different regions. Compliance with local regulatory standards ensures that RFID systems operate within approved limits and avoid interference with other wireless devices.

In summary, RFID technology operates at various frequencies, each with its own advantages and applications. LF, HF, and UHF frequencies cater to different use cases, ranging from close proximity tracking to long-range inventory management. Evaluating the requirements of the RFID application and understanding the characteristics of each frequency band help in selecting the most appropriate RFID reader frequency for a given application.

Low Frequency (LF)

Low Frequency (LF) RFID technology operates at frequencies between 30 kHz and 300 kHz. LF RFID is commonly used in applications that require close proximity tracking and communication. Let’s explore the characteristics and applications of LF RFID technology:

LF RFID offers a shorter read range compared to higher frequency bands. This makes it suitable for applications where reading tags at a close distance is desired. The shorter read range also provides better performance in environments with interference from metals, liquids, or other materials that can affect the RF signal propagation.

One of the primary applications of LF RFID is access control systems. LF tags are often used in access cards or key fobs to grant or restrict access to physical spaces. The close proximity requirement ensures that the tag needs to be in close proximity to the reader for authentication, adding an extra layer of security to access control systems.

LF RFID is also used for animal identification, such as in livestock management or pet tracking. The tags are typically attached to collars or embedded beneath the skin and can be scanned by a reader to identify the specific animal. The close-range capabilities of LF RFID make it well-suited for tracking animals in agricultural or veterinary settings.

Another common application is LF RFID in keyless entry systems for vehicles. LF tags can be integrated into key fobs or installed within the car itself. When the tag is brought into proximity with the reader, it enables unlocking and starting the vehicle without the need for manual key insertion or physical contact.

LF RFID has proven to be reliable and resilient in harsh environments, making it suitable for applications where interference or other obstacles may hinder communication. It is often used in industrial settings for tracking assets or components in manufacturing or warehousing operations.

Overall, LF RFID technology offers a shorter read range but excels in applications that require close proximity tracking, such as access control, animal identification, and keyless entry. Its ability to perform in environments with interference makes it a preferred choice in settings where other frequencies may be less effective. Understanding the unique characteristics and applications of LF RFID helps in selecting the appropriate frequency for specific tracking and identification needs.

High Frequency (HF)

High Frequency (HF) RFID technology operates at frequencies between 3 MHz and 30 MHz. HF RFID is widely used in various applications that require contactless communication and data transfer. Let’s explore the characteristics and applications of HF RFID technology:

HF RFID offers a moderate read range, typically ranging from a few centimeters to a few meters. This makes it suitable for applications where proximity and secure communication are important factors. HF RFID tags and readers are designed to provide reliable performance in environments that may have interference from metals, liquids, or other materials.

One of the major applications of HF RFID is in contactless payment systems. HF tags, embedded in cards or smartphones, are used for secure and convenient payment transactions. The proximity-based communication allows users to simply tap or wave their payment devices near a compatible reader to complete transactions quickly and securely.

HF RFID technology is also extensively used in public transportation systems. Contactless smart cards, equipped with HF tags, are used as fare cards in buses, trains, and subways. Users can easily swipe or tap their cards on the readers at turnstiles or entry points for seamless access and fare deduction.

The library industry also benefits from HF RFID technology for efficient book tracking and management. HF tags are placed within books, allowing for automated check-in and check-out processes. Library patrons can use self-service kiosks or RFID-enabled counter systems to quickly and accurately borrow or return books.

HF RFID finds significant use in healthcare, particularly in patient identification and medical equipment tracking. HF tags embedded in patient wristbands or tags enable accurate identification while minimizing errors. HF RFID is also used to track and manage medical equipment, optimizing inventory control and improving asset management in healthcare facilities.

HF RFID technology is applicable in various other sectors, including supply chain management, asset tracking, and document management. Its moderate range and secure communication capabilities make it suitable for applications that require reliable identification, data transfer, and authentication.

In summary, High Frequency (HF) RFID operates at frequencies between 3 MHz and 30 MHz and offers a moderate read range. It is widely used in contactless payment systems, public transportation, library management, healthcare, and various other industries. Understanding the unique characteristics and applications of HF RFID technology helps in leveraging its benefits for secure and efficient contactless communication and data transfer.

Ultra High Frequency (UHF)

Ultra High Frequency (UHF) RFID technology operates at frequencies between 300 MHz and 3 GHz. UHF RFID is known for its longer read range and ability to process a high volume of tags simultaneously. Let’s explore the characteristics and applications of UHF RFID technology:

UHF RFID offers a longer read range compared to LF and HF frequencies, typically ranging from a few meters to tens of meters, depending on the reader and environmental conditions. This extended range makes UHF RFID suitable for applications that require broader coverage and tracking of tagged items from a distance.

One of the key advantages of UHF RFID is the ability to handle multiple tags simultaneously. The technology enables rapid identification and tracking of a large number of tagged items within the reader’s range. This feature is particularly valuable in applications such as inventory management, retail operations, and supply chain tracking.

In the retail industry, UHF RFID is widely used for inventory management and loss prevention. UHF tags on individual products allow for quick and accurate inventory counts, reducing the time and effort required for manual stocktaking. The real-time tracking capability of UHF RFID also helps identify and prevent theft or unauthorized product movement.

Supply chain and logistics benefit greatly from UHF RFID technology. Tracking goods and assets throughout the supply chain can be efficiently accomplished using UHF tags and readers. From manufacturing to warehousing, distribution, and retail, UHF RFID enables improved visibility, reduced errors, and streamlined operations.

UHF RFID is also used in the healthcare industry for asset tracking, patient management, and medication tracking. UHF tags can be attached to medical equipment, enabling easy and efficient tracking of assets within healthcare facilities. Patient wristbands with UHF tags ensure accurate identification and efficient management of patient records.

Asset tracking in various sectors, such as transportation, aerospace, and construction, also benefits from UHF RFID technology. The longer read range and ability to handle multiple tags make UHF RFID ideal for tracking large or valuable assets across different locations and environments.

UHF RFID is widely adopted in applications that require efficient and scalable identification and tracking of objects or individuals. Its ability to handle a high volume of tags and longer read range makes it suitable for use cases involving large-scale deployments, where cost-effectiveness and efficient data capture are vital.

In summary, Ultra High Frequency (UHF) RFID operates at frequencies between 300 MHz and 3 GHz, providing a longer read range and the ability to handle multiple tags simultaneously. UHF technology finds extensive use in retail, supply chain management, healthcare, and asset tracking applications. Understanding the unique characteristics and benefits of UHF RFID technology helps optimize operations, enhance visibility, and improve efficiency in various industries.

RFID Reader Applications

RFID readers have a wide range of applications across various industries. The ability to accurately and efficiently track and manage objects or individuals using RFID technology has revolutionized processes in sectors such as access control, inventory management, supply chain logistics, retail, and asset tracking. Let’s explore some common applications of RFID readers:

Access Control Systems: RFID readers are widely used in access control systems to grant or restrict entry to secure areas. With RFID-enabled access cards or key fobs, individuals can gain access by simply presenting their RFID credentials to the reader. The reader verifies the credentials and grants access based on predefined security permissions.

Inventory Management: RFID readers are instrumental in automating inventory management processes. By tagging products or assets with RFID tags, organizations can perform accurate and efficient inventory counts. RFID readers enable quick and automated identification of tagged items, eliminating the need for manual scanning of barcodes.

Supply Chain Management: RFID technology plays a crucial role in enhancing supply chain visibility and efficiency. RFID readers enable real-time monitoring of goods as they move through the supply chain, improving inventory accuracy, reducing stockouts, and enhancing order fulfillment. They provide valuable data for optimization, demand forecasting, and process streamlining.

Retail and Point of Sale (POS): RFID readers have transformed the retail sector by improving inventory accuracy and enhancing the customer experience. RFID tags on items allow retailers to perform quick and accurate inventory counts, preventing stockouts and ensuring optimal product availability. RFID-enabled checkout systems enable seamless transactions and faster customer service.

Asset Tracking: RFID readers are used for asset tracking in various industries, including healthcare, transportation, and manufacturing. By attaching RFID tags to valuable assets or equipment, organizations can easily track the location, status, and maintenance history of their assets. RFID readers enable efficient asset management, reducing losses and improving operational efficiency.

Smart Packaging and Logistics: RFID readers are implemented in smart packaging and logistics solutions, enabling real-time tracking and monitoring of packages. By tagging packages with RFID tags, organizations can track and trace shipments, monitor temperature and conditions, and automate logistics processes, ultimately improving supply chain visibility and customer satisfaction.

Document Management: RFID readers are used in document management systems to streamline processes and enhance efficiency. By tagging documents or files with RFID tags, organizations can easily locate and track documents, automate filing and retrieval, and ensure proper document handling and compliance.

These are just a few examples of the numerous applications where RFID readers play a pivotal role. From enhancing security and access control to enabling efficient tracking and management of inventory, assets, and documents, RFID technology has revolutionized various industries, improving operational efficiency, reducing costs, and enhancing customer experiences.

Access Control Systems

Access control systems are one of the key applications of RFID readers, providing secure and efficient entry management to physical spaces. By utilizing RFID technology, access control systems enhance security, streamline processes, and improve overall access management. Let’s explore how RFID readers are used in access control systems:

Identification and Authentication: RFID readers are used to identify and authenticate individuals accessing a secure area. Each individual is provided with an RFID-enabled access card or key fob containing a unique identifier stored in an RFID tag. When the card or key fob is presented near the RFID reader, it reads the tag’s information and verifies it against a database. If the credentials are legitimate, access is granted.

Convenience and Speed: Access control systems utilizing RFID readers offer convenience and speed compared to traditional methods such as key-based systems or manual security checks. Instead of fumbling with keys or requiring physical contact, individuals can simply present their RFID-access credentials near the reader for quick and seamless entry.

Security Permissions and Flexibility: RFID access control systems provide flexibility in managing different security permissions. The RFID reader can be programmed to allow access based on certain conditions, such as time of day, specific personnel, or authorized areas. This granular control allows organizations to customize access rights based on their security protocols and requirements.

Integration with Other Systems: RFID readers can be integrated with other systems to enhance access control functionality. For example, they can be connected to video surveillance systems to record and monitor entry events, or tied to alarm systems to trigger alerts in case of unauthorized access attempts. Integration with visitor management systems allows for efficient tracking and monitoring of guests.

Auditing and Reporting: RFID access control systems provide auditing and reporting capabilities, enabling organizations to track and analyze access events. The system records the date, time, and identity of each access attempt, providing a comprehensive log for analysis, compliance purposes, and investigations in case of security incidents.

Remote Management: With network-enabled RFID readers, access control systems can be remotely managed and monitored. Administrators can update access privileges, monitor access events, and generate reports from a centralized control system, reducing the need for physical presence at multiple access points.

Access control systems using RFID readers are employed in a wide range of facilities, including offices, residential complexes, hospitals, educational institutions, government buildings, and industrial facilities. Their effectiveness in managing access, improving security, and streamlining operations has made them an integral part of modern security infrastructure.

In summary, RFID readers play a crucial role in access control systems, providing secure and convenient access management to physical spaces. Through efficient identification and authentication, flexibility in security permissions, integration with other systems, and auditing capabilities, RFID access control systems enhance security, streamline operations, and improve the overall access management experience.

Inventory Management

Inventory management is a critical process for businesses across various sectors, and RFID readers have revolutionized how inventory is tracked, monitored, and managed. By leveraging RFID technology, organizations can achieve accurate and efficient inventory control, optimize supply chain operations, and improve overall productivity. Let’s explore how RFID readers are used in inventory management:

Real-time Asset Tracking: RFID readers enable real-time tracking of inventory items as they move through the supply chain. Each item is tagged with an RFID tag containing a unique identifier. RFID readers placed strategically at different points in the supply chain automatically identify and capture the tagged items, providing real-time visibility into their location and status.

Automated Inventory Counts: RFID readers streamline inventory counting processes by automating the capture of item data. Instead of manually scanning barcodes or conducting time-consuming physical counts, RFID readers can scan RFID tags on items simultaneously, drastically reducing the time and effort required for accurate inventory checks.

Improved Efficiency and Accuracy: RFID readers greatly improve inventory management efficiency and accuracy. Compared to manual scanning or barcode readers, RFID readers can capture multiple tags simultaneously within their range. This capability allows for quicker and more comprehensive inventory checks, reducing human errors and ensuring accurate inventory records.

Optimized Reordering and Stock Replenishment: By continuously tracking inventory levels in real-time, RFID readers help organizations optimize their reordering and stock replenishment processes. When inventory reaches a certain threshold, the RFID reader can trigger automatic reorder notifications or stock replenishment alerts, ensuring optimal stock levels and minimizing stockouts or excess inventory.

Enhanced Supply Chain Visibility: RFID readers provide end-to-end visibility into inventory as it moves through the supply chain. This visibility enables organizations to identify bottlenecks, monitor order fulfillment, and improve overall supply chain efficiency. RFID technology helps identify and resolve issues promptly, reducing delays and ensuring timely delivery to customers.

Loss Prevention and Security: RFID readers play a crucial role in loss prevention and security by enabling better control and monitoring of inventory. By tagging items with RFID tags, organizations can reduce theft, identify unauthorized movement, and track items in real-time. RFID readers can trigger alerts and notifications in case of any suspicious activities, enhancing overall inventory security.

Integration with ERP Systems: RFID readers can be integrated with enterprise resource planning (ERP) systems or inventory management software, allowing for seamless data integration. Real-time data captured by RFID readers can be automatically synced with the ERP system, providing accurate inventory levels, improving demand forecasting, and facilitating efficient inventory planning.

Inventory management using RFID readers is widely adopted in various industries, including retail, manufacturing, logistics, and healthcare. The technology’s ability to provide real-time visibility, automate inventory processes, reduce errors, and enhance security has transformed inventory management, enabling organizations to streamline operations and achieve cost efficiencies.

In summary, RFID readers revolutionize inventory management by providing real-time visibility, automating processes, improving accuracy, and enhancing security. By leveraging RFID technology, organizations can optimize inventory control, minimize stockouts, streamline supply chain operations, and improve overall efficiency in managing and tracking their inventory.

Supply Chain Management

Supply chain management plays a crucial role in the success of businesses, and RFID readers have transformed how supply chains are managed and optimized. By utilizing RFID technology, organizations can achieve enhanced visibility, streamlined operations, and improved efficiency throughout the entire supply chain. Let’s explore how RFID readers are used in supply chain management:

Real-time Tracking and Tracing: RFID readers enable real-time tracking and tracing of goods as they move through the supply chain. Each item is tagged with an RFID tag containing a unique identifier. RFID readers strategically placed at different stages of the supply chain automatically capture the tag’s information, providing real-time visibility into the location and status of goods. This visibility helps organizations identify bottlenecks, optimize routing, and improve overall supply chain efficiency.

Inventory Accuracy and Optimization: RFID readers improve inventory management accuracy and optimization. By capturing data from RFID tags on items, RFID readers provide real-time visibility into stock levels, minimizing errors and reducing the risk of overstocking or stockouts. Accurate inventory data helps organizations optimize their storage, ordering, and fulfillment processes, improving overall inventory management efficiency.

Efficient Warehouse Operations: RFID readers enhance warehouse operations by automating processes and improving efficiency. RFID technology accelerates picking, packing, and shipping operations by enabling automated identification and tracking of items. RFID readers can quickly and accurately capture item data, reducing manual handling and streamlining overall warehouse operations.

Supply Chain Visibility and Collaboration: RFID readers facilitate improved visibility and collaboration among supply chain partners. By sharing real-time data captured by RFID readers, organizations can collaborate more effectively with suppliers, manufacturers, distributors, and retailers. This shared visibility enables proactive decision-making, quicker response to changes, and improved overall supply chain coordination.

Asset and Equipment Tracking: RFID readers are instrumental in tracking and managing assets and equipment throughout the supply chain. By tagging assets or equipment with RFID tags, organizations can easily track their location, monitor their condition, and optimize maintenance schedules. This monitoring helps reduce loss, prevent unauthorized use, and improve overall asset management efficiency.

Process Automation and Efficiency: RFID readers enable process automation and improve efficiency in supply chain operations. By automating data capture and reducing manual data entry, RFID technology minimizes errors, enhances data accuracy, and expedites processes such as receiving, quality control, and shipping. This automation improves overall process efficiency and reduces operational costs.

Product Authentication and Anti-counterfeiting: RFID readers contribute to product authentication and anti-counterfeiting efforts in the supply chain. By tagging products with RFID tags containing unique identifiers, organizations can verify product authenticity and detect counterfeit items. RFID readers assist in scanning and verifying the tags, helping ensure the integrity and authenticity of products throughout the supply chain.

In summary, RFID readers play a crucial role in supply chain management by providing real-time tracking, enhancing visibility, automating processes, and improving overall efficiency. By leveraging RFID technology, organizations can optimize inventory control, enhance collaboration, streamline operations, and achieve cost efficiencies across the entire supply chain, ultimately improving customer satisfaction and competitiveness.

Retail and Point of Sale (POS)

Retail and Point of Sale (POS) systems are key areas where RFID readers have transformed the way businesses operate, improving efficiency, accuracy, and customer experience. By leveraging RFID technology, retailers can streamline inventory management, enhance checkout processes, and provide a personalized shopping experience. Let’s explore how RFID readers are used in the retail and POS environments:

Inventory Management: RFID readers have revolutionized inventory management in the retail industry. By tagging products with RFID tags, retailers gain real-time visibility into inventory levels and locations. RFID readers enable quick and accurate inventory counts as items pass by readers or are scanned with handheld devices. This automation minimizes manual efforts, reduces inaccuracies, and provides up-to-date inventory information.

Product Availability and Stock Control: RFID readers significantly improve product availability and stock control. With RFID tags providing accurate and real-time inventory data, retailers can quickly identify low stock levels, prevent stockouts, and optimize replenishment processes. This ensures that popular items are always available on shelves, enhancing the customer shopping experience.

Enhanced Checkout Processes: RFID technology speeds up checkout processes, reducing customer waiting times. RFID-enabled products can be simultaneously scanned by RFID readers at the point of sale, eliminating the need for manual scanning or barcode scanning one item at a time. This streamlined checkout process improves the overall shopping experience and customer satisfaction.

Promotions and Customer Engagement: RFID readers enable targeted promotions and customer engagement initiatives. By incorporating RFID technology into loyalty cards or smart displays, retailers can identify customer preferences and provide personalized recommendations or discounts based on purchase history. This targeted approach enhances customer engagement and increases the effectiveness of promotional efforts.

Loss Prevention and Security: RFID readers contribute to loss prevention and security in retail environments. By tagging items with RFID tags, retailers can monitor and prevent inventory shrinkage, theft, or unauthorized movement of items. RFID readers at exits can trigger alerts if items with active RFID tags are detected, helping prevent shoplifting and improving overall security measures.

Supply Chain Visibility: RFID readers play a crucial role in supply chain visibility for retailers. By tracking items from the manufacturer to the store shelves, RFID readers enable real-time visibility into the movement of goods. This visibility helps optimize logistics, improve forecasting, and ensure timely replenishment, reducing product delays and stockouts.

Data Analytics and Business Intelligence: RFID readers provide valuable data for retail analytics and business intelligence. By capturing data on customer preferences, inventory movement, and purchase patterns, retailers can gain insights into consumer behavior, optimize store layouts, improve product placements, and make informed business decisions.

In summary, RFID readers have revolutionized the retail and POS environments by improving inventory management, enhancing checkout processes, ensuring product availability, and providing personalized customer experiences. Leveraging RFID technology in retail operations enhances efficiency, reduces costs, and gives retailers a competitive edge in the ever-evolving retail landscape.

Asset Tracking

Asset tracking is a critical aspect of business operations, and RFID readers have significantly improved the efficiency and accuracy of asset tracking processes. By utilizing RFID technology, organizations can easily track and monitor the location, movement, and status of assets in real-time. Let’s explore how RFID readers are used in asset tracking:

Real-time Location Tracking: RFID readers provide real-time tracking of assets as they move within a facility or across different locations. Each asset is tagged with an RFID tag containing a unique identifier. RFID readers strategically placed throughout the facility can automatically capture and communicate the tag information, allowing organizations to monitor asset locations and ensure their availability when needed.

Improved Visibility and Inventory Control: RFID readers enable improved visibility and inventory control of assets. By tagging assets with RFID tags, organizations can quickly locate and identify them using RFID readers. This eliminates the need for manual search efforts, reducing the time and effort required for inventory checks and improving overall inventory accuracy.

Efficient Maintenance and Inspections: RFID readers streamline maintenance and inspection processes for assets. By integrating asset management software with RFID readers, organizations can schedule and track maintenance activities. RFID tags on assets can be scanned, triggering automated maintenance alerts or providing access to maintenance history and instructions, fostering efficient asset maintenance and increasing uptime.

Loss Prevention and Security: RFID readers play a vital role in preventing asset loss and enhancing security. By tagging assets with RFID tags, organizations can monitor and restrict unauthorized movement or theft of assets. RFID readers at exits can trigger alerts if assets with active RFID tags are detected, increasing overall security measures and reducing the risk of asset loss or misplacement.

Streamlined Auditing and Compliance: RFID readers simplify asset auditing and ensure regulatory compliance. During an audit, RFID readers can quickly identify and validate assets, reducing the time and effort required for manual checks. RFID readers automatically capture asset data, enabling efficient record-keeping, ensuring compliance, and simplifying asset tracking for regulatory purposes.

Integration with Asset Management Systems: RFID readers seamlessly integrate with asset management software systems, creating a centralized platform for asset tracking and management. RFID reader data is synced with the asset management system, providing a comprehensive view of asset location, status, and maintenance history. This integration enhances the efficiency and effectiveness of asset tracking processes.

Quick Inventory and Asset Search: RFID readers simplify and speed up inventory checks and asset searches. By using handheld RFID readers, organizations can quickly scan areas or specific zones to identify assets and verify their presence. This reduces manual search efforts, improves visibility, and saves time when conducting inventory or asset audits.

In summary, RFID readers have greatly streamlined asset tracking processes by providing real-time location tracking, improving visibility, and enhancing security measures. RFID readers enable organizations to efficiently track assets, streamline maintenance operations, prevent loss, ensure regulatory compliance, and improve overall operational efficiency.

Conclusion

RFID readers are integral to various industries, enabling efficient and accurate tracking, monitoring, and management of objects and assets. With the ability to communicate wirelessly and capture data from RFID tags, these readers have transformed processes in applications such as access control systems, inventory management, supply chain logistics, retail, and asset tracking.

The basics of RFID technology, including passive and active tags, frequency bands, and backscatter communication, provide the foundation for understanding how RFID readers operate. Antennas, transceivers, controllers, and power sources collectively work to power up and communicate with RFID tags, enabling seamless data collection and transmission.

RFID readers operate at different frequencies, including low frequency (LF), high frequency (HF), and ultra-high frequency (UHF), each offering specific benefits for different applications. LF is ideal for close proximity tracking, HF provides moderate range and secure communication, while UHF brings long-range capabilities and the ability to handle multiple tags simultaneously.

Through various applications, RFID readers have been instrumental in enhancing access control systems, improving inventory management efficiency, optimizing supply chain operations, and revolutionizing retail and point-of-sale experiences. They facilitate real-time asset tracking, streamline processes, reduce errors, enhance security measures, and provide valuable data for analysis and decision-making.

In conclusion, RFID readers play a vital role in enabling seamless communication with RFID tags and facilitating the exchange of information in different industries and applications. With their ability to capture, process, and transmit data, these readers have transformed how businesses manage access, track inventory, optimize supply chains, and enhance customer experiences. As technology continues to evolve, RFID readers will continue to play a pivotal role in shaping and improving processes across a wide range of sectors, ultimately driving efficiency, accuracy, and profitability in the increasingly fast-paced and interconnected world.