Hidden Gold Extraction Techniques At South Dakota’s Sanford Underground Research

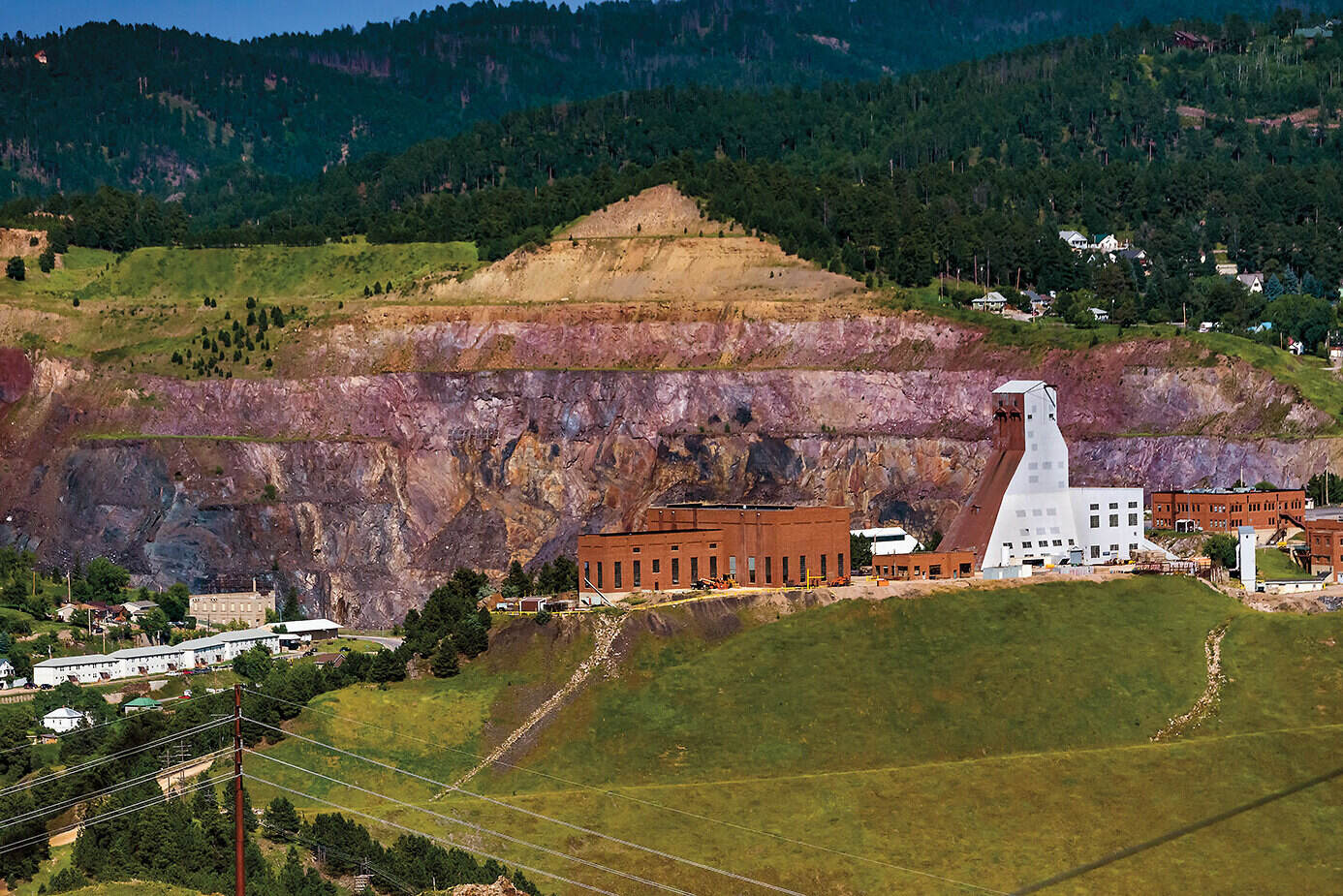

Have you ever wondered how gold extraction works deep underground? At South Dakota's Sanford Underground Research Facility, scientists use advanced techniques to uncover this precious metal. Located in the Black Hills, this facility isn't just a mine; it's a hub for cutting-edge research. Here, experts study everything from particle physics to geology, all while perfecting methods to extract gold efficiently and safely. This underground lab provides a unique setting where researchers can test new technologies and refine existing ones. Curious about the secrets hidden beneath the surface? Let's dig into the fascinating world of gold extraction at Sanford Underground Research Facility.

Hidden Gold Extraction Techniques at South Dakota's Sanford Underground Research Facility

South Dakota's Sanford Underground Research Facility (SURF) isn't just a hub for cutting-edge scientific research. It also holds secrets to some of the most fascinating gold extraction techniques. Let's delve into these hidden methods that have been used to extract gold from the depths of the Earth.

Gravity Separation

Gravity separation is one of the oldest methods for extracting gold. This technique relies on the difference in density between gold and other materials.

Panning: This age-old method involves swirling water and sediment in a pan to separate gold from other particles. The heavier gold settles at the bottom while lighter materials wash away.

Shaking Tables: These tables use a shaking motion to separate gold from other minerals. The table's surface is slightly inclined, and as it shakes, gold moves to one side while other materials move to the opposite side.

Cyanidation

Cyanidation is a chemical process that has been used for over a century to extract gold from ore. It involves dissolving gold in a cyanide solution.

Heap Leaching: In this method, crushed ore is piled into heaps and sprayed with a cyanide solution. The solution percolates through the heap, dissolving gold, which is then collected at the base.

Vat Leaching: Similar to heap leaching, but the ore is placed in large vats. The cyanide solution is added, and the mixture is agitated to speed up the dissolution process.

Flotation

Flotation is a process that separates minerals based on their ability to attach to air bubbles.

- Froth Flotation: Crushed ore is mixed with water and chemicals to create a slurry. Air is then blown through the mixture, creating bubbles. Gold particles attach to the bubbles and float to the surface, where they are skimmed off.

Amalgamation

Amalgamation involves using mercury to extract gold from ore.

- Mercury Amalgamation: Mercury is mixed with crushed ore, forming an amalgam with gold. The amalgam is then heated, vaporizing the mercury and leaving behind pure gold.

Bioleaching

Bioleaching uses bacteria to extract gold from ore. This environmentally friendly method is gaining popularity.

- Bacterial Oxidation: Certain bacteria can oxidize sulfide minerals, releasing gold trapped within. The bacteria are added to the ore, and over time, they break down the minerals, freeing the gold.

Electrowinning

Electrowinning is a process that uses electric currents to extract gold from a solution.

- Electrolytic Cells: Gold-rich solution from cyanidation or bioleaching is passed through electrolytic cells. An electric current is applied, causing gold to deposit onto electrodes.

Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL)

These methods involve using activated carbon to extract gold from a solution.

Carbon-in-Pulp (CIP): Crushed ore is mixed with a cyanide solution, and activated carbon is added. Gold adsorbs onto the carbon, which is then separated from the slurry and processed to extract the gold.

Carbon-in-Leach (CIL): Similar to CIP, but the activated carbon is added to the slurry before cyanidation. This allows for simultaneous leaching and adsorption, making the process more efficient.

Pressure Oxidation

Pressure oxidation is a pre-treatment method used to make refractory ores more amenable to gold extraction.

- Autoclave Processing: Ore is placed in an autoclave, where it is subjected to high pressure and temperature in the presence of oxygen. This breaks down sulfide minerals, releasing gold for subsequent extraction.

Thiosulfate Leaching

Thiosulfate leaching is an alternative to cyanidation, using a non-toxic chemical to dissolve gold.

- Thiosulfate Solution: Crushed ore is treated with a thiosulfate solution, which dissolves gold. The gold-rich solution is then processed to recover the metal.

Conclusion

South Dakota's Sanford Underground Research Facility has been a treasure trove of gold extraction techniques. From ancient methods like panning to modern innovations like bioleaching, these techniques have evolved to make gold extraction more efficient and environmentally friendly.

The Future of Gold Extraction

South Dakota's Sanford Underground Research Facility is a game-changer for gold extraction. Using advanced techniques, this facility is setting new standards in the mining industry. The focus on sustainability and efficiency ensures that gold mining has less environmental impact while maximizing yield. Researchers and engineers are constantly innovating, making the process safer and more effective.

This facility isn't just about mining gold; it's about pioneering methods that could be used worldwide. The lessons learned here could transform how we think about resource extraction. As technology advances, expect even more breakthroughs from this cutting-edge research hub.

Sanford Underground Research Facility is more than a mine; it's a glimpse into the future of mining. With its innovative techniques, it promises a brighter, more sustainable future for gold extraction. Keep an eye on this facility; it's leading the way in mining innovation.